The Growing Plastic Waste Problem

Plastic waste is a huge issue. Every year, millions of tons of plastic end up in landfills and the ocean, causing pollution and harming wildlife. Finding ways to reuse plastic is important, and one exciting solution is turning plastic waste into 3D printing filament. This could help reduce pollution and create useful new products at the same time.

How Recycled Plastic Can Be Used in 3D Printing

3D printing works by building objects layer by layer using different materials, including plastic. Instead of using new plastic, some companies and individuals are finding ways to turn used plastic bottles, food containers, and other waste into filament.

The process involves collecting and cleaning plastic waste, shredding it into tiny pieces, melting it down, and shaping it into thin strands. These strands, called filament, can be fed into a 3D printer to create new objects. This approach not only reduces plastic waste but also makes 3D printing more sustainable and eco-friendly.

Challenges of Using Recycled Plastic in 3D Printing

While the idea sounds great, there are some challenges to using recycled plastic for 3D printing:

- Inconsistent Quality: Recycled plastic may have different properties, making printing unpredictable.

- Contamination: Dirt, food, and dyes in plastic waste can lower the quality of the final product.

- Not All Plastics Work: Some types of plastic, like certain soft plastics, don’t melt well for 3D printing.

- Weaker Filament: Recycled filament might not be as strong as new plastic, limiting what it can be used for.

- High Processing Costs: Sorting, cleaning, and processing plastic waste takes time and money.

Despite these challenges, many researchers and companies are working to improve the process and make it more efficient.

Success Stories in Recycling Plastic for 3D Printing

Many companies and innovators have already made progress in using recycled plastic for 3D printing. Some inspiring projects include:

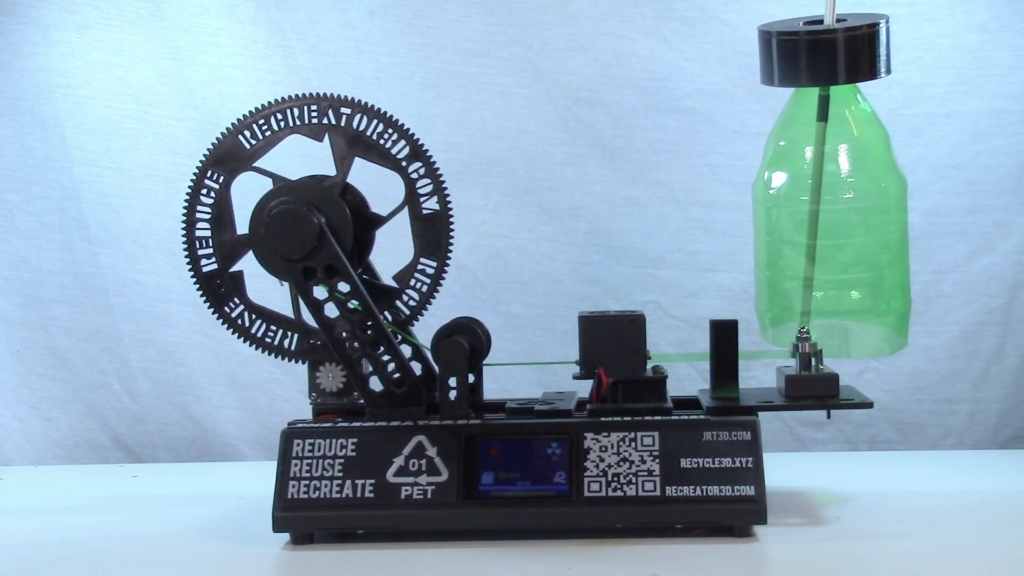

- Precious Plastic: A global community that creates machines to recycle plastic waste into new products, including 3D printing filament.

- Filabot: A company that sells machines to help people turn plastic waste into 3D printer filament at home.

- Reflow Filament: A company that transforms plastic waste collected from developing countries into high-quality filament.

- RecycleBot: A low-cost device that allows people to recycle plastic waste into usable filament on their own.

These initiatives prove that recycling plastic into 3D-printed products is not just an idea—it’s already happening.

The Future of Sustainable 3D Printing

As technology advances, more businesses and individuals are expected to use recycled plastic filament for 3D printing. This shift could help reduce plastic waste and promote sustainability. Scientists are also working on improving the strength and reliability of recycled filaments so they can be used for a wider range of products, from simple household items to industrial tools.

Governments and environmental groups can also play a role by encouraging recycling programs and supporting businesses that use recycled materials. If more people get involved, the process will become cheaper and more accessible.

Conclusion

Recycling plastic into 3D-printed products is not only possible—it’s already being done. While there are challenges, new technologies and innovative companies are making it easier to use recycled plastic for 3D printing. As more people and businesses adopt this practice, we can help reduce plastic waste and create new products in a sustainable way.

Are you ready to explore 3D printing with recycled plastic? Let’s turn waste into something amazing!

Explore More

Interested in how 3D printing can bring your ideas to life? Our 3D printing services cover a wide range of materials and techniques, ensuring precision and quality for every project. From featured works that showcase our craftsmanship to innovative material options, we provide solutions tailored to your needs. If you’re looking for a custom print, feel free to request a quote via our contact page for more details. Want to deepen your knowledge of 3D printing? Check out our other blogs, where we share insights, tips, and industry trends to keep you informed. Want to stay updated? Follow our Facebook page!

Leave a Reply